Many jobs require working in tanks, vaults or silos. But what makes these spaces especially dangerous? That’s where the confined space entry permit comes in. This isn’t just red tape or another piece of paper work; it’s a critical life saving checklist that separates a routine job from a disaster.

This guide breaks down what a confined space entry permit is, why it matters so much, who’s involved and the safety procedures you must follow—all in simple terms.

What "Confined Space" Actually Means

First “confined space” doesn’t just mean a small area. According to safety bodies like OSHA, it’s any space that meets all three of these conditions:

- Is large enough for a person to enter and work.

- Has limited or restricted means of entry or exit.

- Is not designed for continuous human occupancy.

Think of industrial tanks, sewers, pipelines or grain silos. The most important thing you need to know is a Permit-Required Confined Space (PRCS).

This is a confined space that also has one or more known or potential hazards, such as a toxic atmosphere, risk of being engulfed by material or internal shape that could trap someone. Because of these dangers you are legally required to have a formal permit to enter.

Why Is a Confined Space Entry Permit So Important?

Entering a permit required space without a plan is a deadly gamble. The air you’re breathing could be low on oxygen or full of toxic fumes you can’t see or smell. The material in a silo could shift and engulf a worker in seconds.

These “silent killers” are why confined space incidents are so often fatal. Worse still they often result in multiple casualties when an untrained “would be hero” rushes in to help their colleague and becomes a second victim.

The permit is the solution. It forces a “safety time out” for the entire team to stop, identify every risk and write down the exact steps to control them before anyone enters.

The Dangers: Common Confined Space Hazard

The entire permit system is designed to manage these specific confined space hazards

- Engulfment: The risk of being buried or trapped by a liquid (like in a tank) or a flowing solid (like grain in a silo).

- Physical/Mechanical Hazards: Things like moving machine parts that haven’t been turned off, live electrical wires or a risk of falling.

- Configuration Hazards: Spaces with walls that slope inward or floors that taper, which can trap an entrant.

- Atmospheric Hazards: This is the #1 risk. It includes low oxygen (asphyxiation), flammable or explosive gases or toxic fumes like carbon monoxide.

The Legal Side: OSHA and Safety Standards

This isn’t just a good idea—it’s the law. In the United States the OSHA confined space permit standard (1910.146) legally mandates this entire process. This regulation requires employers to identify all permit required spaces, prevent unauthorized entry and have a detailed written program and permit system to protect their workers.

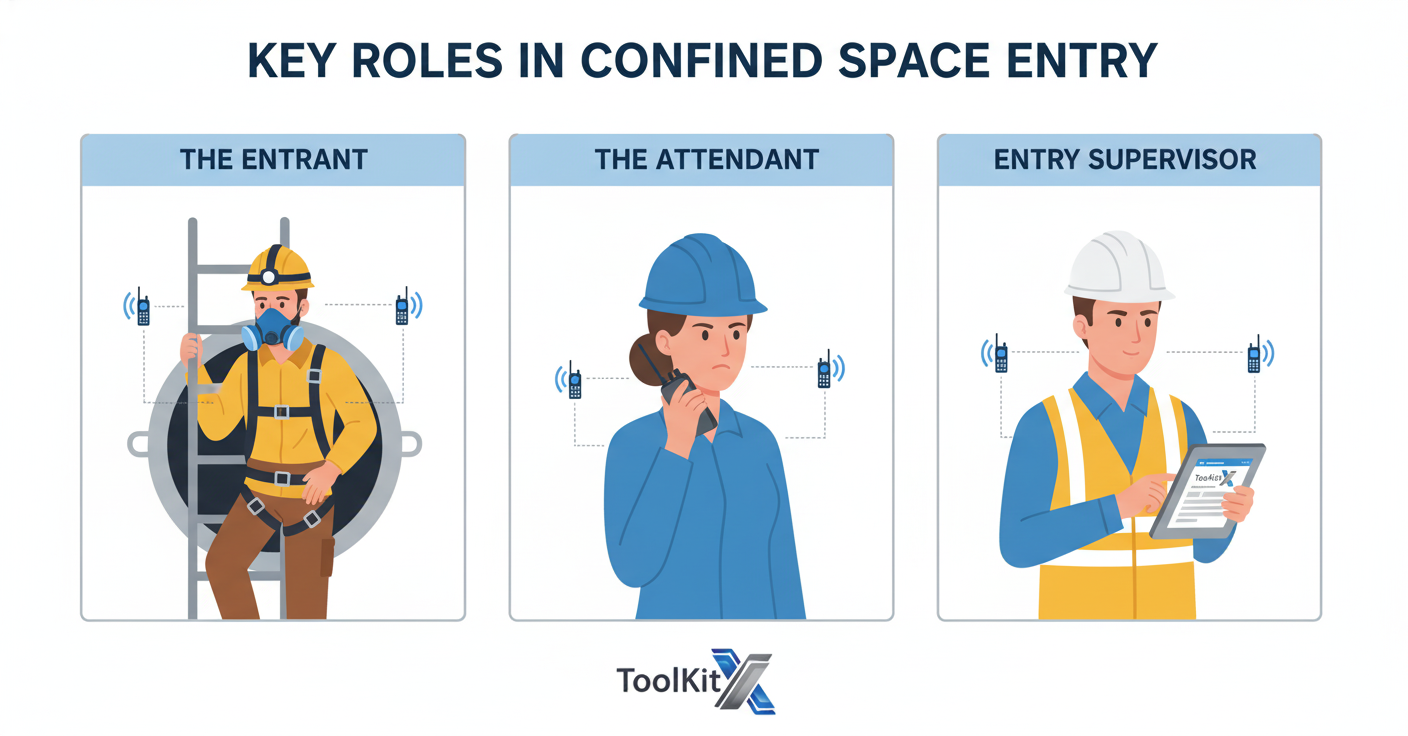

The 3 Key People Involved in Every Entry

A safe entry is never a one person job. It’s a team effort with three clearly defined roles.

The Entrant (The person going inside)

This is the trained worker (or workers) authorized to enter the space. They must know the hazards, be in constant communication with the Attendant and know how to evacuate immediately if an alarm sounds or they feel unsafe.

The Attendant (The "lookout" staying outside)

This person is the entrant’s lifeline. The confined space attendant duties are to monitor the entrant and conditions, maintain communication and summon the rescue team if needed. The Attendant must never enter the space even in an emergency.

The Entry Supervisor (The person in charge)

This person has ultimate authority over the entry. The entry supervisor responsibilities include verifying all safety checks are done, confirming the rescue team is ready and signing the permit to authorize entry. They also close the permit once the job is safely finished.

What's On the Permit? (Key Components of the Checklist)

While permits can be customized all confined space entry permit requirements must include these core elements. Think of it as the ultimate pre-flight checklist.* Job Details & Team: Where is the space? What work is being done? Who is the entrant, attendant and supervisor?

- Entry Duration: A specific time limit for how long the permit is valid.

- Hazard Identification: A checklist of all potential hazards (atmospheric, engulfment etc.).

- Hazard Control Measures: A list of what has been done to make it safe (e.g. "Space has been ventilated", "Lines have been locked-out/tagged-out").

- Atmospheric Testing Results: This is essential. A log showing the air was tested before entry (for oxygen, flammability and toxins) with the results, time and tester’s initials.

- PPE & Rescue Plan: A list of all required gear (like harnesses or respirators) and the specific emergency rescue plan.

- Authorization Signature: The Entry Supervisor’s signature, confirming all checks are complete and it’s safe to enter.

The 6 Steps of a Confined Space Entry Procedure

The permit document is the final part of a larger confined space entry procedure. Here is the 6 step process from start to finish.

- Planning and Assessment: Long before the job a qualified person assesses the space and the work. They identify all hazards and develop the specific hazard control and rescue plans.

- Issuing the Permit: The Entry Supervisor begins filling out the permit, documenting the team, the work and the known hazards.

- Preparing the Space (Testing, Ventilating, Isolating): This is the “make-it-safe” step. It involves isolating energy sources (lockout/tagout), testing the air (from top, middle and bottom), and ventilating with fans if necessary. All results are logged on the permit.

- The Entry: Only after the Supervisor signs the permit can the Entrant go in. The Attendant takes their post and work begins. Air monitoring often continues throughout the job.

- Completing the Job and Exiting: The Entrant finishes the work and exits the space. They confirm with the Attendant and Supervisor that all personnel and equipment are out.

- Closing and Canceling the Permit: The Entry Supervisor verifies the job is done and the space is clear. They then formally sign off, closing and canceling the permit.

Tired of Paperwork? Digitize Your Permit System with ToolkitX

Paper-based systems are slow, messy and create huge compliance headaches in the modern workplace.

What happens when a permit gets wet? How do you prove compliance to an auditor months later?

This is where ToolkitX transforms your safety program. Our digital Permit to Work (ePTW) module moves your entire confined space entry procedure into a simple, powerful app on a phone or tablet.

With ToolkitX, you can:

- Go Digital, Not Paper: Issue, review and approve permits from any device. No more clipboards, no more lost forms.

- Ensure Compliance, Every Time: Our smart templates can force fields like atmospheric testing to be filled, so no critical steps are missed.

- Get Instant Access: Pull up any active, pending or past permit in seconds. Audits become a breeze.

- Track in Real-Time: See which permits are active, who is in the space and when a permit is due to expire, all from a central dashboard.

Stop managing binders of paper and start managing your team’s safety. See how ToolkitX can simplify your entire safety workflow.

Schedule a free demo @ https://toolkitx.com/campaign/permit-to-work/