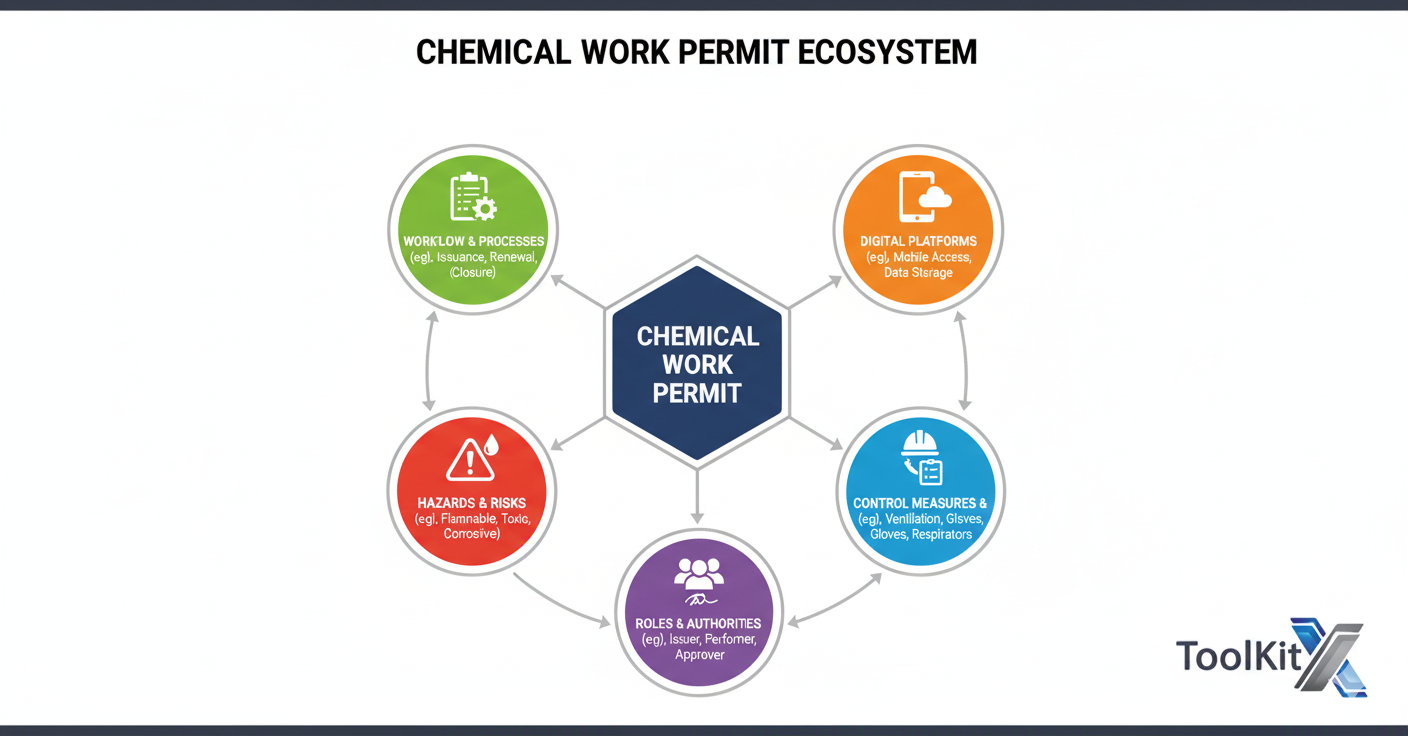

Working with chemicals in an industrial environment requires control, responsibility and planning. One mistake – improper ventilation, mixing incompatible chemicals or not isolating equipment – can result in toxic exposure, fires or environmental disasters. A chemical work permit is a formal safety control that ensures hazardous chemical tasks are evaluated, authorized and performed under the right conditions.

This guide explains what a chemical work permit is, when you need one, the must haves and how digital Permit to Work platforms like ToolkitX can simplify the whole process.

What Is a chemical work permit?

A chemical work permit is an official written document that authorizes a specific task with hazardous chemicals. It confirms that all risks have been assessed, controls are in place and qualified personnel have approved the work.

Unlike a standard work instruction, a chemical work permit includes:

- Job description and scope

- Chemical hazards involved

- SDS (Safety Data Sheet) references

- PPE required

- Isolation and lockout steps

- Environmental precautions

- Authorization details

- Monitoring requirements

This permit acts as a high level safety barrier within a wider Permit to Work (PTW) system to stop workers from doing chemical work without controls.

Why chemical work permits are important

Chemical work is high risk, toxic vapours, corrosive substances, flammable liquids and reactive materials. Without a permitting process, organisations can have fires, burns, chemical spills or fatal exposures.

How chemical work permits protect workers

Chemical work permits help you:

- Identify and assess hazards before work starts

- Prevent unauthorized work

- Enforce standardised safety procedures

- Assign accountability across teams

- Track compliance with OSHA, HSE & internal rules

- Be prepared for emergencies

What happens if you don’t have a chemical work permit

Not having a formal permit system can lead to:

- Uncontrolled chemical reactions

- Inhaling toxic gases

- Corrosion related equipment failure

- Environmental contamination

- Serious injuries or fatalities

A chemical work permit protects workers and the organisation from legal, environmental and operational risks.

When do you need a chemical work permit?

A chemical work permit is required when a task exposes workers to chemicals beyond normal operational limits

Common scenarios that require a permit

1. Handling & transferring chemicals

Loading or unloading drums, filling tanks or transferring liquids between units.

2. Mixing or diluting chemicals

When reactions may generate heat, fumes or pressure build-up.

3. Tank, vessel, or pipeline cleaning

Residues in confined spaces can release toxic or flammable vapours.

4. Chemical sampling & laboratory testing

Where exposure to concentrated chemicals is possible.

5. Maintenance in chemical processing areas

Even routine maintenance can expose workers to hazardous residues.

6. Waste handling & disposal

Neutralising agents, effluents or hazardous by-products.

If any task can cause toxic contact, inhalation, splashes, reactions or contamination a chemical work permit is required – not optional.

Key requirements of a chemical work permit

A permit is more than just filling out a form. It requires competent evaluation, planning and communication across teams.

1. Hazard identification & risk assessment

The first step involves analyzing:

- The chemicals being used

- SDS classifications

- Exposure risks: inhalation, skin, ingestion

- Flammability, corrosiveness, reactivity

- Environmental impact

This risk profile determines what controls are required.

2. Isolation & lockout procedures

Before work begins, you must isolate:

- Chemical lines

- Valves

- Pumps

- Heating or cooling systems

- Electrical equipment

Isolation ensures chemical flow is fully stopped, preventing accidental mixing or spills during the job.

3. Control measures & safety precautions

Depending on the job, controls may include:

- Ventilation or exhaust systems

- Vapor monitoring

- Spill containment kits

- Fire suppression equipment

- Neutralization materials

- Barriers & signage

Control measures should be documented clearly and verified before the job starts.

4. Required PPE

The permit should specify exact PPE types, such as:

- Chemical-resistant gloves

- Full-body splash suits

- Respirators or SCBA

- Goggles, face shields

- Rubber boots

- Acid/alkali-proof aprons

PPE must match the chemical hazard level—not generic site PPE.

5. Authorization & competency

Only trained and competent personnel must:

- Issue the permit

- Approve isolation steps

- Supervise the task

- Close the permit

Authorization ensures responsibility and prevents unauthorized work execution.

6. Monitoring & ongoing controls

Active monitoring ensures conditions remain safe throughout the job:

- Gas testing

- Temperature measurements

- Leak detection

- Pressure monitoring

- Vapor concentration checks

Permits should specify monitoring intervals and responsible persons.

7. Permit validity, completion & closure

A chemical work permit must:

- Have a fixed start and end time

- Be closed by the supervisor

- Include final inspection

- Document cleanup, equipment restoration, and residual hazards

Proper closure prevents misunderstandings or unsafe site conditions.

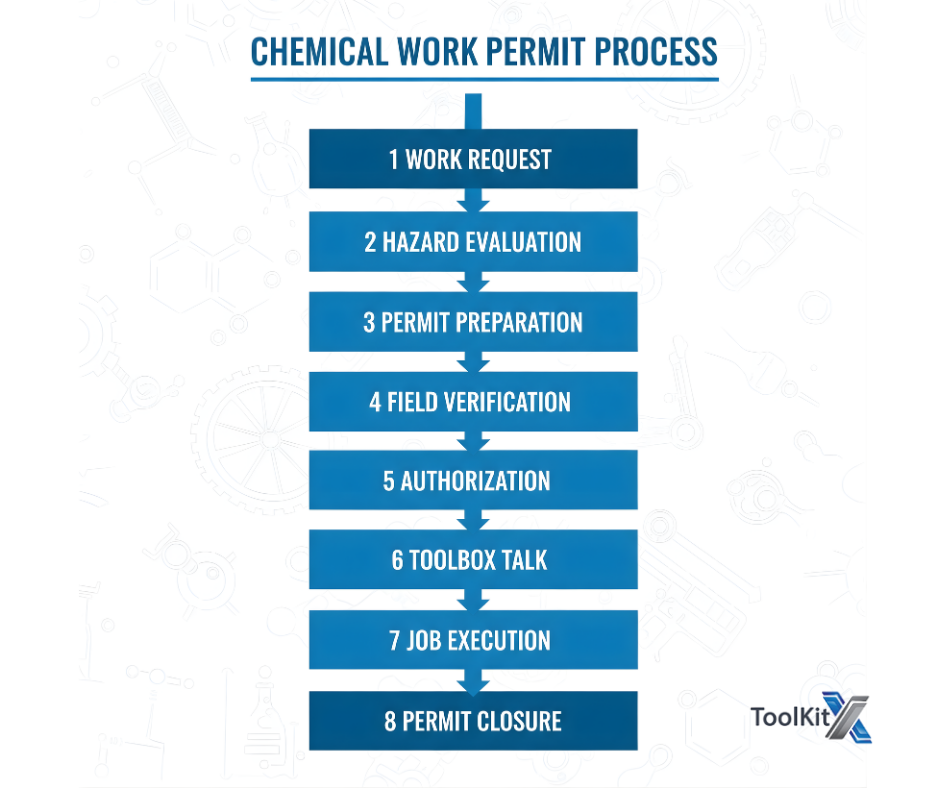

Step-by-Step process for issuing a chemical work permit

Here is a best-practice workflow followed by leading industrial facilities:

Step 1: Work request

Requester provides:

- task

- Chemicals

- Location

- Duration

- Personnel

Step 2: Hazard & risk evaluation

Safety teams review:

- SDS

- Chemical hazards

- Location-specific risks

- reactions or spill risks

Step 3: Permit preparation

Permit includes:

- controls

- PPE

- Isolation

- Environmental precautions

- Monitoring schedule

Step 4: Field verification

Before approval:

- Work area is checked

- Controls are verified

- Equipment is isolated

Step 5: Authorization & sign off

Permit is signed by:

- Supervisor

- HSE officer

- Area manager (if required)

Step 6: Pre-work toolbox talk

Workers discuss:

- Hazards

- PPE

- Emergency plans

- Roles & responsibilities

Step 7: Job execution & monitoring

Supervisors ensure:

- Controls are in place

- Atmospheric is safe

- No changes occur without re-approval

Step 8: Job completion & permit closure

After work:

- Area is checked

- Waste and residues are removed

- Isolation is removed

- Permit is closed and archived

Chemical work permit checklist

A chemical work permit template should have:

- Permit number & expiry

- Description of work

- Chemical hazards

- PPE required

- Isolation checklist

- Test results

- Control measures

- Emergency response procedures

- Signatures

Templates save time and reduce guesswork.

Common mistakes to avoid

Even structured systems fail when teams forget the basics. Don’t:

- Leave out risk assessments

- Get PPE wrong

- Forget to isolate valves or drains

- Miss gas tests

- Work outside permit validity

- Poor communication between teams

- Paper based tracking errors

These are the top causes of chemical incidents worldwide.

Digital chemical work permits – The ToolkitX advantage

Many are moving away from paper permits to digital systems for better control, efficiency and safety. ToolkitX for example:

- Customisable chemical permit templates

- Mobile approvals and field verification

- Automated permit expiry reminders

- Real time monitoring & alerts

- Digital isolation tagging

- Audit trails for compliance

- Instant reporting & analytics

Digital PTW systems reduce delays, prevent human error and improve consistency – so you can work safer and smarter

A chemical work permit is a critical component of industrial safety. It ensures hazardous chemical tasks are planned, authorised, monitored and executed under controlled conditions. By having good procedures – and moving to digital PTW tools like ToolkitX – you can reduce chemical risk, improve compliance and increase operational reliability.

Book a free demo @ https://toolkitx.com/campaign/permit-to-work/